DESIGN.

CREATE.

DELIVER.

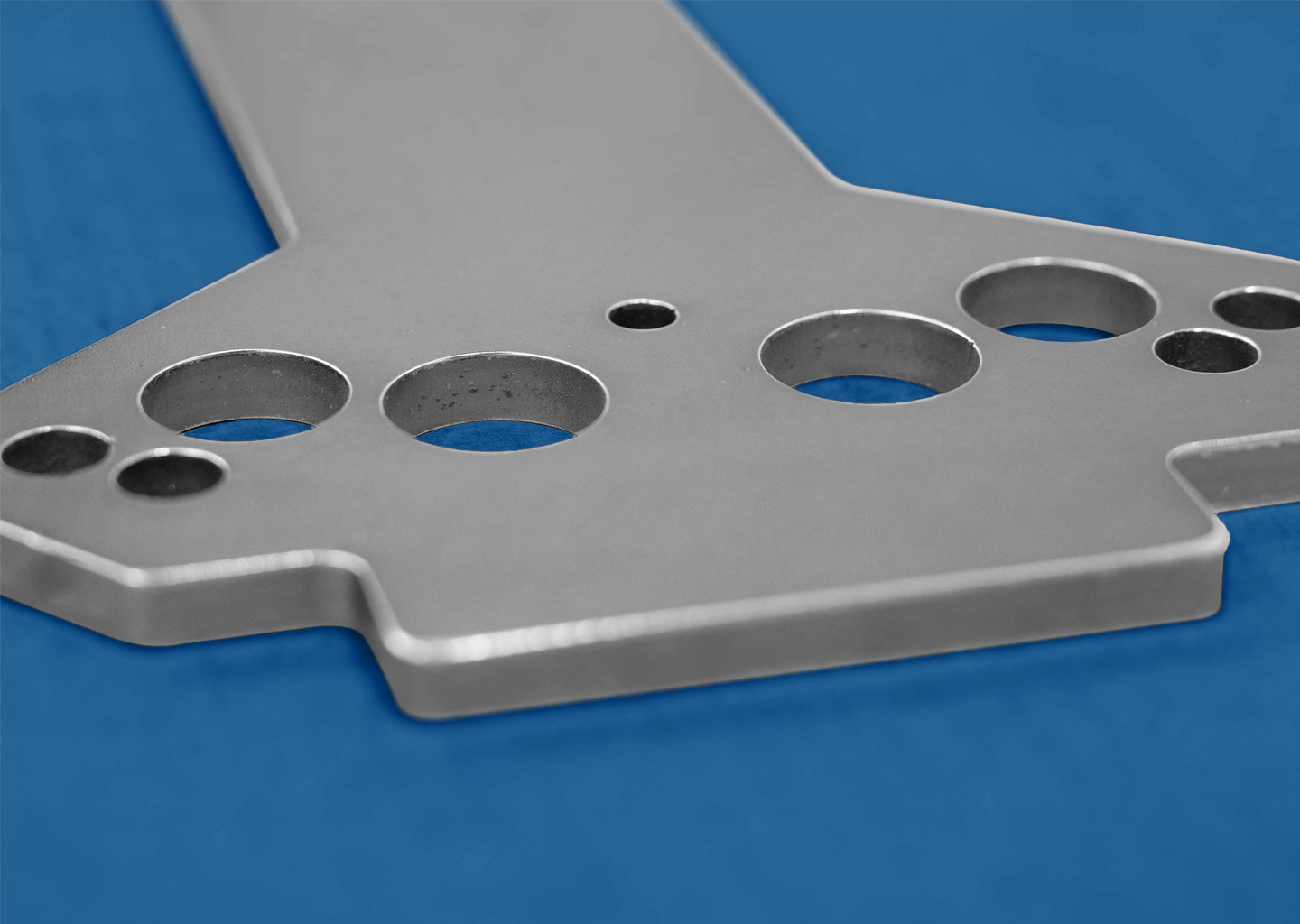

AUTOMATED DEBURRING

We can offer you a value-added deburring service to lasercut or punched profiles, utilising the most innovative grinding and deburring machines available.

This is a dry process, meaning there’s no requirement for drying and no dangerous grinding residue.

Separate machines for Steel, Stainless Steel and Aluminium

We process Steel, Stainless Steel and Aluminium through separate machines to eliminate cross-contamination and potential fire risk from grinding dust.

Steel is processed through our LISSMAC machine. This machine is capable of deburring the top and bottom side of the profile in one pass to a maximum width of 1500mm.

Stainless Steel and Aluminium are processed through our Timesavers machine. This machine deburs one side at a time, to a maximum width of 1100mm.

Timesavers 32-Series WRBW

- Maximum Width 1100mm

- Minimum Sheet Thickness 0.5mm

- Minimum Part Size 50mm x 50mm

LISSMAC SBM-L1500

- Maximum Width 1500mm

- Minimum Sheet Thickness 0.5mm

- Minimum Part Size 250mm x 50mm

VIBRO DEBURRING

- Separate machines for different materials

- Capability to deburr pressed or welded assembles, as well as flat parts